Powder or paste - what’s the best additive for my product?

Have you ever wondered about the differences between Graphene Oxide paste and powder? Both forms of Graphene Oxide have unique properties, and understanding the differences between them is key to choosing the right material for your applications.

Graphene oxide paste is a highly concentrated suspension of graphene oxide in water, that is easy to spread, dilute, and handle. The paste has high viscosity and it is ideal for applications that require a dilution of the paste to create e good GO dispersion at low concentration, such as coatings and membranes.

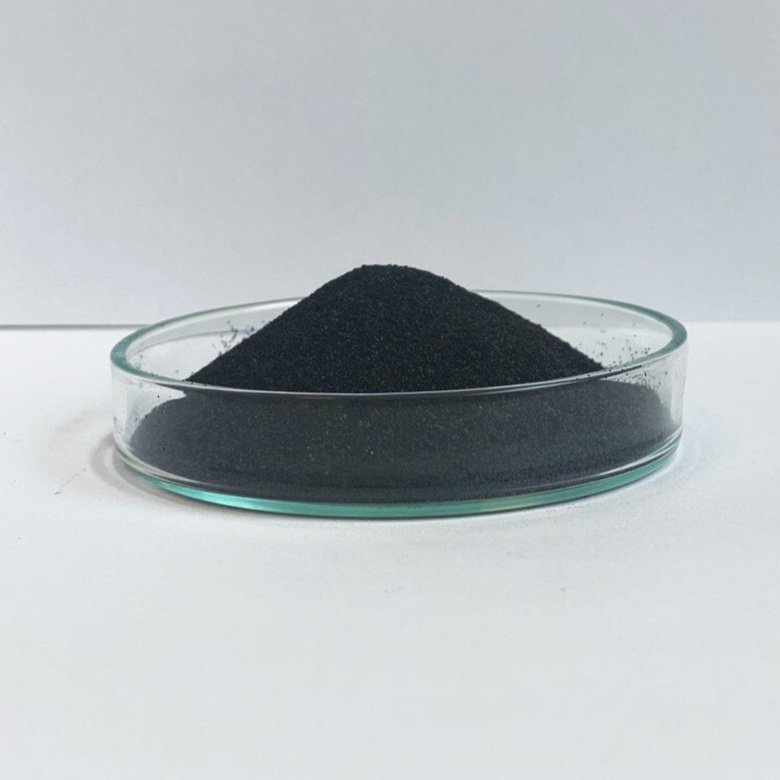

Graphene oxide powder is a dry form of graphene oxide that is ideal for applications that require good stability and precise dosing, such as composite materials. Moreover, the powder simplifies shipping of large quantities.

When it comes to choosing between graphene oxide paste and powder, the decision ultimately depends on the specific requirements of your application and of your processing methodology. Our team of experts can assist you in choosing the right form of graphene oxide that will bring you the best results.

Why choosing GO Powders?

Different mesh sizes are available: Depending on the end-use, researchers and industries can choose a particular mesh size that best suits their requirements, allowing for precise granularity control.

Free-flowing powder and dispersibility: LayerOne offeres three GO dry powder products with different mesh sizes. The GOX8® Graphene Oxide P935, with less than 35 mesh is a free-flowing powder easy to handle, mix and distribute evenly in various formulations. GOX8® Graphene Oxide P9100 with less than 100 mesh is a fine powder easy to disperse, while GOX8® Graphene Oxide P950, with a mesh size between 50 and 100 mesh strikes the right balance in terms of flowability and dispersibility.

Convenient shipping of GO: Shipping raw materials can sometimes be challenging due to the harsh conditions of long-distance transport. When stored as dry powder, GO is compact and stable, ensuring that the material is received unaltered and ready to use.

Customizable dispersions: GO powder can be re-dispersed in water or in other polar solvents at customizable specific concentrations. To make stable dispersion in water, and achieve high GO exfoliation, we recommend to use low concentrations (<0.04 wt.%) and using a probe sonicator for at least 30 minutes.

Easy to process into composites: GO powder’s consistency allows for seamless blending with other materials, ensuring optimal results in the final product.

Why choosing GO pastes?

Various concentrations, viscosity, acidity levels: GO pastes come with various characteristics, allowing users to select a paste that aligns perfectly with their project specifications, ensuring optimal results. LayerOne offers three main paste products:

GOX8® Graphene Oxide AH920: a highly acidic paste, with 20 wt. % GO concentration. A cost-effective product, ideal for applications where low pH are tolerated.

GOX8® Graphene Oxide AA925: an acidic paste, with 25 wt.% GO concentration. An highly concentrated and versatile product that can be used in multiple processes and applications.

GOX8® Graphene Oxide AL910: a de-acidified paste, with 10 wt.% GO concentration. A premium product for pH sensitive applications.

Easy handling and processing: The consistency of GO paste makes it especially user-friendly. Whether you're spreading it over a surface or incorporating it into a mixture, its manageability ensures a dust-free process.

Can be diluted to a stable GO dispersion: This ensures that even when the paste is spread thin or mixed with other substances, the integrity of the graphene oxide remains intact.

Customizable to your specific needs: GO paste can be customized to match your specific requirements, whether it's adjusting the concentration, viscosity, pH, or any other characteristic.

Safe transport: even if pastes are a less-effective way to transport pure GO respect to powder, their water medium enhances safety by better absorbing thermal shocks during long-distance transport.

Choosing between Graphene Oxide paste and powder is more than just a matter of physical form; it's about aligning the material's unique features with your processing requirements.

Still unsure about which form is right for you? Our team of experts is here to help. Together, we can ensure that you leverage the full potential of Graphene Oxide in its most effective form.

LayerOne GOX8 Graphene Oxide Paste

LayerOne GOX8 Graphene Oxide Powder