Eco-friendly packaging with graphene materials

Graphene is an excellent barrier for gas and water, making it a promising material for creating sustainable packaging for food and household products.

Graphene monolayer, with its flawless 2D structure, acts as an exceptional barrier, preventing the diffusion of gases and liquids through its plane, while possessing remarkable mechanical strength and transparency. This unique combination of properties makes it an ideal choice for various packaging applications.

Graphene-coated paper in food or household packaging prevents oxygen diffusion, preserving contents and blocking gas and liquid escape. This way shelf life of the products is extended, while ensuring quality and freshness. Ideally, graphene could replace aluminium in multilayer packaging, serving as a complete gas and water barrier. This protects the product, significantly boosts recyclability, and reduces weight and transport costs.

The synthesis of large-area, defect-free, single-crystalline, monolayer graphene is still extremely challenging and not yet commercially available for industrial large-scale industrial applications. However, multi-stacking of small graphene layers can be an effective way to overcome these limitations, creating effective packaging materials that are scalable and economically viable.

Three main routes have been evaluated to create packaging materials with commercially available graphene such as few-layer graphene (FLG), graphene oxide (GO) and reduced Graphene Oxide (rGO):

Coating of a paper or polymeric surface with FLG and rGO

Incorporation of FLG, GO, or rGO into a polymeric matrix

Creating a GO coating on a surface and reducing it to create a multi-stacked rGO barrier

Each of these versatile methods offers unique strategies for enhancing packaging materials, with varying industrial processability and scalability.

Coating of a paper or polymeric surface with FLG and rGO

Creating a thin-layer coating of multi-stacked graphene flakes on top of a paper or polymeric surface is a simple and effective way to create an impermeable barrier that decreases oxygen and water transmission rate. The coating can be created on various surfaces using dip- or rod-coating, technologies that are easy to scale at industrial use.

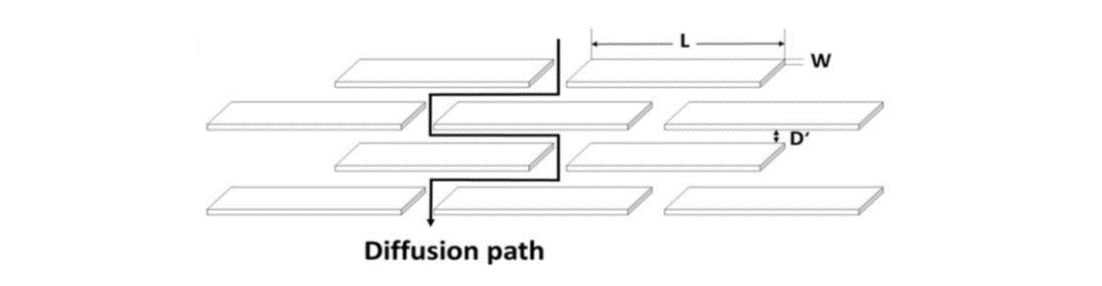

Each single layer of material act as gas barrier, creating a tortuous diffusion path (see figure below), which increases indefinitely the speed of permeation of gas and moisture across the coating barrier. Graphene's hydrophobic nature poses challenges in achieving homogeneous coating without delamination and defects. The creation of macroscopic holes and grain boundary defects during the coating process allow gas diffusion, hindering the creation of a flawless barrier.

Incorporation of FLG, GO, or rGO into a polymeric matrix

FLG, GO, and rGO can be incorporated into a polymeric matrix to create a graphene/polymer nanocomposites. To enhance gas-barrier properties, nonporous nanomaterials, having a high aspect ratio, are often added to polymer matrices, creating a filler that blocks gas diffusion. These nanofillers increase tortuosity, lengthening the gas's path through the polymer nanocomposites. Despite their exceptional gas-barrier properties, graphene layers often aggregate due to their strong face-to-face interactions, leading to reduced barrier effectiveness in resulting polymer nanocomposites.

Creating a GO coating on a surface and reducing it to create a multi-stacked rGO barrier

Due to its hydrophilic nature, GO can be processed easily in water and polar solvents, enabling large-scale application as a thin-layer coating using methods like spraying, rod- and dip-coating. The resulting multi-stacked GO laminate is impermeable to gases in a dry state. However, GO's susceptibility to water and moisture can compromise its barrier properties. To overcome this, chemically or thermally reducing GO, forms interlocked rGO layers, creating an effective barrier against gases and moisture (see image below). The rGO layer is also chemically inert, ensuring resistance against acids and aggressive chemicals commonly found in packaged products.

Graphene's high thermal and electrical conductivity also makes it ideal for smart packaging, detecting temperature or pressure changes and triggering indicators or alarms for spoilage. It can also enhance anti-counterfeiting measures by embedding chemical or electronic identifiers in packaging materials.

Are you interested in testing graphene materials for your packaging applications? Contact us to discuss which of these methodologies are best suited for your application.

References:

Byung Min Yoo et. al, J. Appl. Polym. Sci., 2014, DOI: 10.1002/APP.39628

Y. Su et. al, Nat. Comm., 2014, DOI: 10.1038/ncomms5843