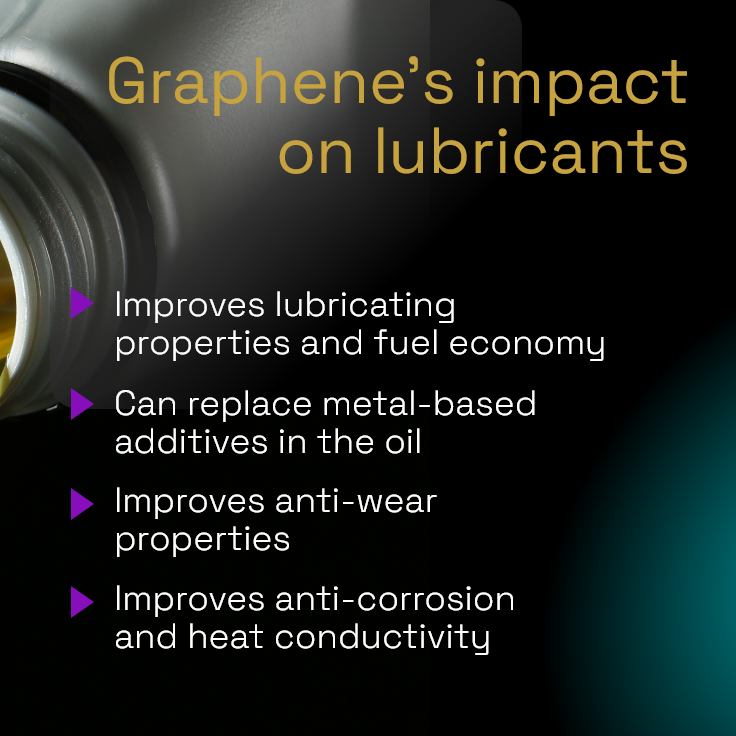

Revolutionize lubricant performance with graphene

Innovation is key to maximize the performance and longevity of lubricating oils. Graphene, with its multitude of exceptional properties, is stepping into the limelight as a game-changer for lubricating oils.

Enhanced lubricating properties and fuel economy

Graphene's unique structure allows it to reduce friction at the molecular level. When introduced into lubricating oils, graphene particles create a thin, protective layer on surfaces, minimizing wear and tear. This prolongs the lifespan of machinery parts and improves their efficiency. A reduction in friction translates to better fuel economy in engines, leading to cost savings and reduced carbon footprints.

A sustainable alternative to metal-based additives

Traditionally, lubricating oils have relied on metal-based additives to enhance their performance. However, these additives come with environmental concerns, both in their extraction and in the potential for them to leach into our ecosystems. Graphene, being a carbon-based material, offers a sustainable and environmentally-friendly alternative. It can replicate, if not surpass, the performance benefits of these metal-based additives, reducing environmental impact.

Superior anti-wear properties

The durability of machinery is often compromised by wear and tear, leading to frequent maintenance and replacements. With the introduction of graphene into lubricating oils, a protective barrier forms around components, effectively shielding them from abrasive particles and contaminants. This can prolong equipment life, reduce maintenance intervals, and give considerable cost savings for businesses.

Enhanced anti-corrosion and heat conductivity

Corrosion is a persistent challenge in many mechanical systems, leading to reduced performance and eventual breakdowns. Graphene, with its chemical properties, can act as a barrier, preventing corrosive elements from reaching and reacting with metal surfaces.

Additionally, graphene's impressive heat conductivity is another benefit for lubricating oils. Efficient heat transfer ensures that machinery operates at optimal temperatures, reducing the risk of overheating and the associated wear and damage. This is especially important in high-performance systems where temperature regulation is paramount.

The combination of graphene's high surface area, robust mechanical attributes, and impressive corrosion resistance holds the potential to redefine the standards of the lubricant industry. As industries strive for enhanced performance and sustainability, graphene-enhanced lubricating oils emerge as a front-runner in delivering on both fronts.

If you’re interested in exploring how graphene can be integrated into your lubricants, we’re here to assist. Let’s shape the future of lube oils together!